MIL-DTL-17376F

4. VERIFICATION

4.1 Conformance inspection. Conformance inspection shall consist of the visual examination

for defects listed in table I. Unless otherwise specified (see 6.2), the manufacturer shall select the type

of sampling plan (attribute, variable, or continuous) in accordance with MIL-STD-1916.

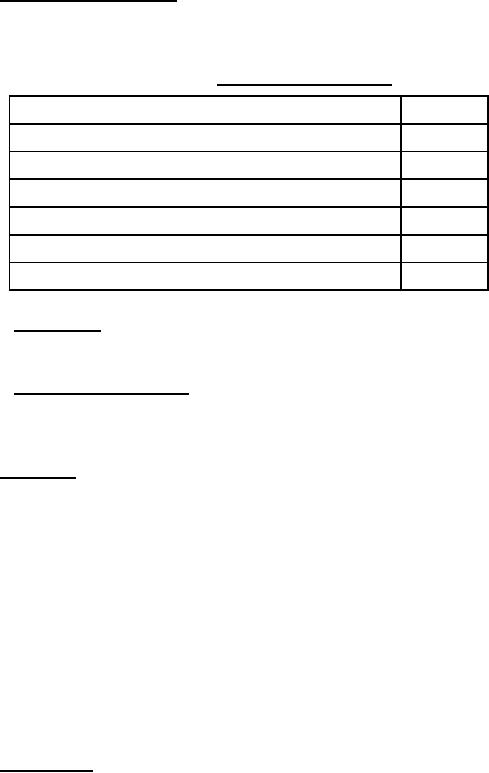

TABLE I. Classification of defects.

Defect

Major

Material not as specified

101

Dimensions not as specified

102

Screw threads not as specified

103

Reinforcement not as specified

104

Weight of cap in excess of 3-1/2 pounds

105

Cleaning, treating and painting not as specified

106

4.1.1 Sample size. The sample size shall be selected in accordance with level 1 of tables I,

II, and III of MIL-STD-1916.

4.1.2 Classification of defects. Major defects noted should be classified as shown in table I.

5. PACKAGING

5.1 Packaging. For acquisition purposes, the packaging requirements shall be as

specified in the contract or order (see 6.2). When packaging of materiel is to be performed by

DoD or in-house contractor personnel, these personnel need to contact the responsible packaging

activity to ascertain packaging requirements. Packaging requirements are maintained by the

inventory control point's packaging activities within the military service or defense agency, or

within the military service's system command. Packaging data retrieval is available from the

managing military department's or defense agency's automated packaging files, CD-ROM

products, or by contacting the responsible packaging activity.

6. NOTES

(This section contains information of a general or explanatory nature that may be helpful,

but is not mandatory.)

6.1 Intended use. The caps and flanges covered by this specification protect cylinder

valves against damage in shipping, handling, and storage.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business