MIL-DTL-22606D(SH)

SEAL WELD PROCEDURE

PREPARATION - Torque plug to 800±200 foot-pounds.

Clean area to be seal welded including abutting faces of cylinder neck and plug.

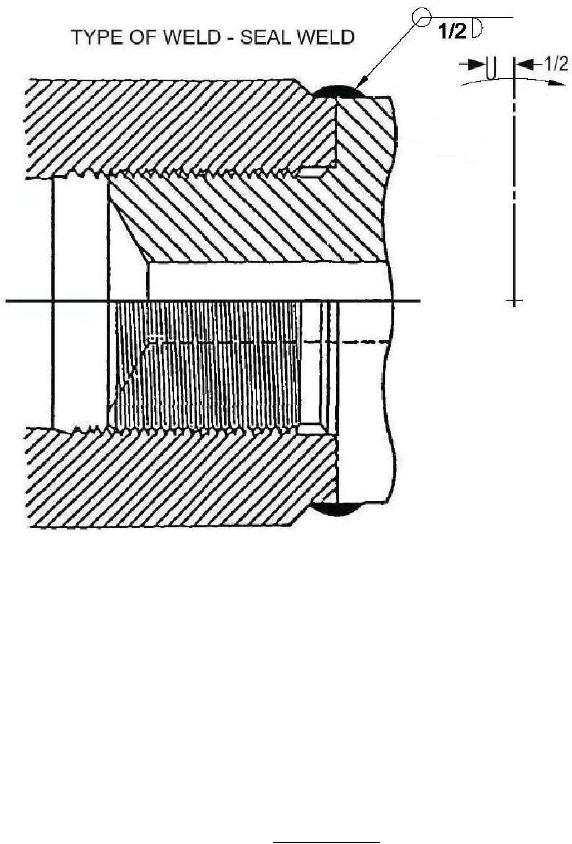

POSITION - Horizontal roll with electrode ½ inch ahead of top center as illustrated.

PREHEAT - 100 to 200 °F maximum.

ELECTRODE - MIL-309-16 in accordance with MIL-E-22200/2 preferred, using DC reverse polarity current at 24

to 26 volts and 80 to 100 amps.

NO. OF BEADS - Two, with all starts and stops staggered. Clean slag with blunt tool and stainless steel wire brush

before continuing a weld.

ARC TRAVEL SPEED - 1st layer at 9 to 11 inches per minute.

2nd layer at 8 to 12 inches per minute.

FIGURE 11. Typical seal weld.

28

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business