MIL-DTL-22606D(SH)

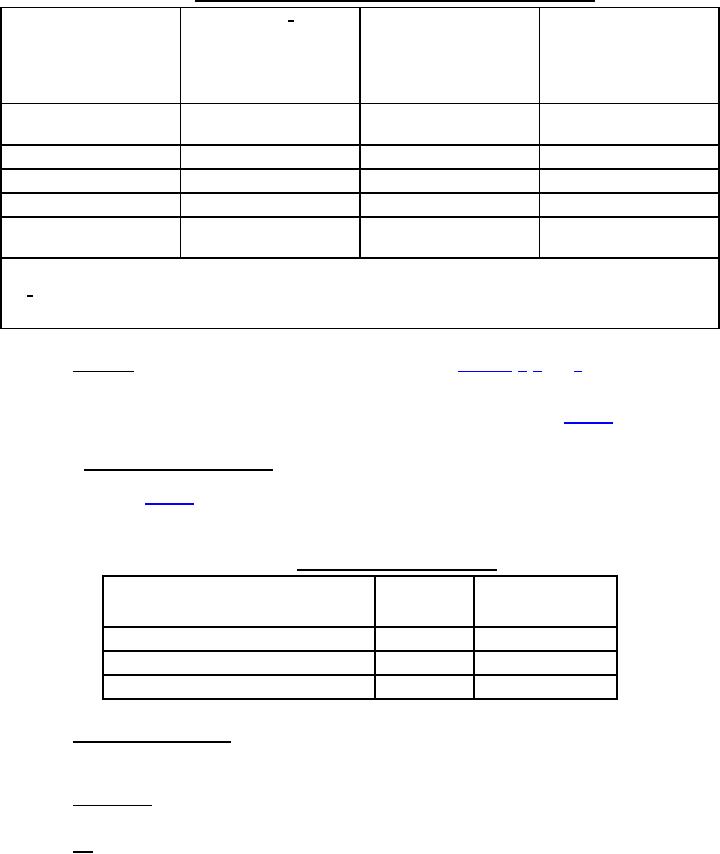

TABLE II. Minimum mechanical properties, flasks, skirts, and bearing blocks.

Flasks 1/

ASTM A336/A336M

Skirts

Bearing blocks

Mechanical property

Grade F22

HY-80/100 IAW

ASTM A572/A572M

ASTM A335/A335M

T9074-BD-GIB-010/300

Grade P22

90,000 (min)

90,000 (min)

Yield strength at 0.2%

42,000 (min)

130,000 (max)

130,000 (max)

offset (psi)

Tensile strength (psi)

110,000 (min)

63,000 (min)

110,000 (min)

Elongation in 2 inches (%)

15 (min)

21 (min)

15 (min)

Brinell hardness (BHN)

229 (min)

-

-

Charpy V-notch at -70 °F

35 (min)

-

35 (min)

(foot-pounds)

NOTE:

1/

For Class 5500 flasks, yield strength at 0.2% offset shall be 98,400 psi (min) and tensile strength shall be

120,000 psi (min). All other flask mechanical properties shall be as specified.

3.1.4 End plugs. Unless otherwise specified (see 6.2), end plugs (see figures 3, 4, 5, and 6) for Service A and

Service C flasks shall be fabricated from bar stock or forged from material conforming to ASTM A322 Grade 4130.

If bar stock is used, a minimum reduction ratio of 3-to-1 from solidified cross-sectional area to bar cross-sectional

area shall be provided. End plugs shall be heat-treated to achieve the properties specified in table III when tested as

specified in 4.3.2.1.

3.1.4.1 Oxygen and special flask plugs. Inlet/outlet plugs and drain plugs for Service B flasks shall be hot

finished nickel-copper in accordance with the chemistry of QQ-N-281, Class A, and shall have mechanical

properties specified in table III. Material chemistry shall be verified by testing as specified in 4.3.1 and mechanical

properties verified by testing as specified in 4.3.2.1.

TABLE III. Mechanical properties, end plugs.

ASTM A322

QQ-N-281 Class A

Mechanical properties

Grade 4130

hot finished

Yield strength at 0.2% offset (psi) (min)

55,000

30,000

Tensile strength (psi) (min)

85,000

75,000

Elongation in 2 inches (%) (min)

15

26

3.1.5 O-rings and back-up rings. O-rings shall be made of fluorocarbon rubber in accordance with

SAE-AMS7259. O-rings more than 36 months old at time of initial flask shipment from the manufacturing facility

shall not be used. Back-up rings shall be made of virgin polytetrafluoroethylene (PTFE).

3.1.6 Inerting caps. Inerting caps shall be constructed of material capable of withstanding a minimum pressure

of 100 pound-force per square inch gauge (psig). All surfaces shall be corrosion resistant.

3.1.7 Oil. Oils used in the production process during fabrication shall be of the type that will fluoresce under

the ultraviolet light examination specified in 4.2.3.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business