MIL-DTL-22606D(SH)

3.1.8 Mercury. Unless otherwise specified (see 4.5), vendor shall provide certification that each flask is

mercury-free. Mercury-bearing instruments or equipment which may cause contamination shall not be used in

manufacture, fabrication, assembly, or testing unless such instruments or equipment are protected by a double

containment boundary.

characteristics of seamless flasks shall be as specified in table I, and figures 1 and 2 when inspected as specified in

4.2.2. The flask out of roundness shall not exceed 2 percent of the flask outside diameter (OD). For Type CD and

3.2.1 Wall thickness. Unless otherwise specified (see 6.2), flasks shall be manufactured with the design wall

thickness specified in table I.

3.2.1.1 Wall thickness exception. A wall thickness less than that specified in table I is acceptable provided the

wall thickness is equal to or greater than the thickness specified in table IV for the actual tensile strength of flask

material determined after final heat treatment, and all other tests and inspection requirements are met. Flasks may

have isolated areas where the wall thickness is less than that specified in table IV if the reinforcement of that

isolated area meets the requirements of section UG-40 of the ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1. The minimum wall thickness in the neck to head transition area (see figure 12) shall be equal to or

greater than 75 percent of the minimum design wall thickness specified in table I. Exceptions for flask classes and

outside diameters other than those listed in table IV shall be submitted to NAVSEA, via the contracting agency, for

approval on a case by case basis.

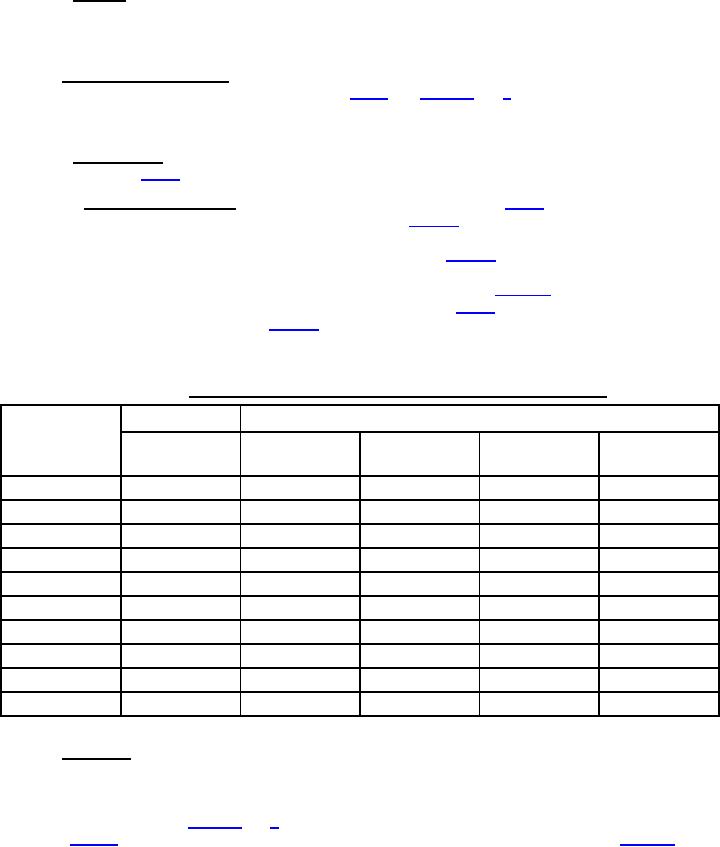

TABLE IV. Minimum allowable wall thickness based upon actual tensile strength.

Class 3000

Class 5000

Actual tensile

6⅝ OD

strength of

18 OD

10¾ OD

18 OD

20 OD

material (psi)

(inches)

(inches)

(inches)

(inches)

(inches)

112,000

0.551

0.489

0.562

0.917

1.010

114,000

0.542

0.483

0.553

0.902

0.993

116,000

0.534

0.478

0.545

0.888

0.997

118,000

0.525

0.473

0.536

0.874

0.962

120,000

0.517

0.468

0.528

0.860

0.947

122,000

0.509

0.463

0.520

0.847

0.932

124,000

0.502

0.458

0.513

0.834

0.918

126,000

0.494

0.454

0.505

0.822

0.904

128,000

0.487

0.449

0.498

0.810

0.891

130,000

0.480

0.445

0.491

0.798

0.878

3.3 Fabrication. Flasks may be fabricated of either seamless tubular material or pierced and drawn billets.

Flask pipe material shall be 100 percent ultrasonically inspected in accordance with T9074-AS-GIB-010/271 to

verify adequate wall thickness exists prior to fabrication. The adequacy of the wall thickness shall consider

reductions that will occur due to scaling and grit blasting. The body of Types GF, SF, and GFS flasks shall be a

straight cylinder as shown on figures 1 and 2. The body of Types CD and CDS flasks shall be a curved cylinder as

shown on figure 1. Each end shall be hot formed to provide a neck for the flask end connections (see figure 12).

The Type SF flask may be fabricated with a steel ring shrunk onto the neck to achieve the required 4.25-inch neck

OD. The ring shall be of the same material as the flask and shall have a 0.002-inch minimum interference fit. Skirts

and bearing blocks for Types GFS and CDS flasks shall be as specified (see 6.2).

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business